Quality

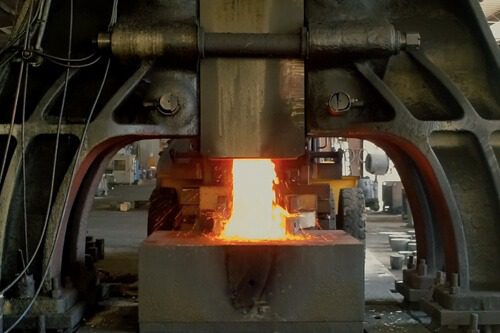

With over 75 years of forging and manufacturing experience, Western Forge & Flange has developed one of the most efficient Quality management system in today’s forge and flange industry. Our Quality team consists of a Quality Director, Metallurgist, Quality Assurance Technicians, Quality Control Inspectors, Nondestructive Testing inspectors, and final Inspectors, who work day in and day out to ensure the integrity and quality of our products. Our manufacturing processes are designed around the operational excellence of our people, pragmatic systems and preventative and continual improvement.

Western Forge & Flanges’ Quality Management system complies with the following standards:

- ISO 9001:2015 Standard

- PED 2014/68/EU, Annex I, Section 4.3

- PER Schedule 1A and Schedule 2 Part 4-31 (6) (7) (8)

- NCA3800/4200 ASME SECTION-III (Nuclear)

- NQA-1 (Nuclear)

- CSA N285.0 (Canadian Nuclear)

- CSA B51 (Canadian Non-Nuclear)

- MIL-I-45208A (Military Standard)

- 10CFR50 APP-B (Code for Federal Regulation – Nuclear)

- 10CFR21 (NRC Regulation)

- DFARS regulatory and statutory requirements

- ITAR

- CFSI

Compliance Certificates

ISO 9001 2015

PED Certificate

PER Certificate

TSSA Certificate (Nuclear)

TSSA Certificate (Non-Nuclear)

Quality Policy

Western Forge will maintain its distinction in providing world class “Quality Forging Solutions” with its unique capabiliities and quality standards maintained for decades.

Western Forge regards it as its duty to manufacture products in the most economically viable way that meets or exceeds the requirement and expectations of our customers. Western Forge’s management is committed to put constant effort to improve the organization, the quality of the products and the working environment.

Quality Control Inspections

Raw Material

100% Receiving Inspection

Sawing

In-process QC Inspection

Forging

100% In-process QC Inspection

Heat Treated

(if required)

100% In-process QC Inspection

Machining

100% In-process QC Inspection

Marking

First Article Inspection

Final Inspection

100% Inspection

Shipping

Job Complete

Testing

Western Forge & Flange can accomplish any type of testing as per specification and/or customer specific requirements. Western uses ISO 9001 & ISO 17025 accredited and approved laboratories, whom we audit every year. Our Metallurgist analyzes the results to ensure that our parts meet or exceed all requirements.

Mechanical Testing

- Tensile Testing

- Hardness Testing

- -Brinell Hardness (HBW) || Rockwell Hardness (HR) ||Vickers Micro-hardness (HV)

- Impact Testing

- Charpy Impact Testing ||Izod Impact Testing

- Metallography Analysis

Metallography Analysis

- Microstructure Examination

- Macrostructure Examination

- Grain Size Determination

- Volume Fraction Point Count

Non-Destructive Testing

- Ultrasonic Testing

- Liquid Penetrant Testing

- Magnetic Particle Testing

Corrosion Testing

- Intergranular Attack in Austenitic Stainless Steels per ASTM A262 – Practice A, B, C, E, F

- Intergranular Corrosion in Nickel-Rich, Chromium Alloys per ASTM G28 Method A

- Pitting and Crevice Corrosion Resistance of Stainless Steels in Ferric Chloride Solution per ASTM G48 Method A, B, D

- Detrimental Intermetallic Phase in Duplex Stainless Steels per ASTM A923 Method A, C

Chemistry Analysis

- Optical Emission Spectroscopy (OES)

- Combustion (LECO) Analysis for Carbon, Sulfur, Nitrogen, Oxygen, and Hydrogen

- X-Ray Fluorescence (XRF) for Positive Material Identification (PMI)

Conflict Minerals Policy

Western Forge & Flange is committed to ensuring the safety and protection of people worldwide. We support ending the violence and human rights violations in the mining of certain minerals from a location described as the “Conflict Region.”

The definition of “conflict minerals” refers to gold, as well as tin, tantalum, and tungsten, regardless of where they are sourced, processed or sold. The U.S. Secretary of State may designate other minerals in the future. The U.S. Securities and Exchange Commission adopted final rules to implement reporting and disclosure requirements related to “conflict minerals,” as directed by the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010. We support these requirements to further the humanitarian goal of ending violent conflict in designated regions, which has been partially financed by the exploitation and trade of “conflict minerals”.

Our Commitment

- Support the aims and objectives of the U.S. legislation on the supply of “conflict minerals”.

- Do not knowingly procure specified materials that originate in the “conflict region”.

- Ensure compliance with these requirements and ask our suppliers to undertake reasonable due diligence with their supply chains to assure that specified metals are not being sourced from conflict regions.

If we discover the use of these minerals in products we sell to be “non-conflict free”, in any material, parts or components we procure, we will take appropriate actions to transition products to be “conflict free”.

If you need a copy of Western CMRT, please email: quality@western-forge.com

Sincerely,

Director of Quality

Approved

Manufacturer List

Our Philosophy

Safety

Responsible

Aware

Vigilant

Quality

Reliable Every Time

Meet or Exceed Requirements / Expectations

People

Positive

Determined

Professional

Growth

Sustainable

Performance

Satisfied Customer

Ready To Get Started?

Once you reach out to Western Forge & Flange, you’ll get the products you need in a hurry. Quick quotes and dependable delivery are part of our promise to you.