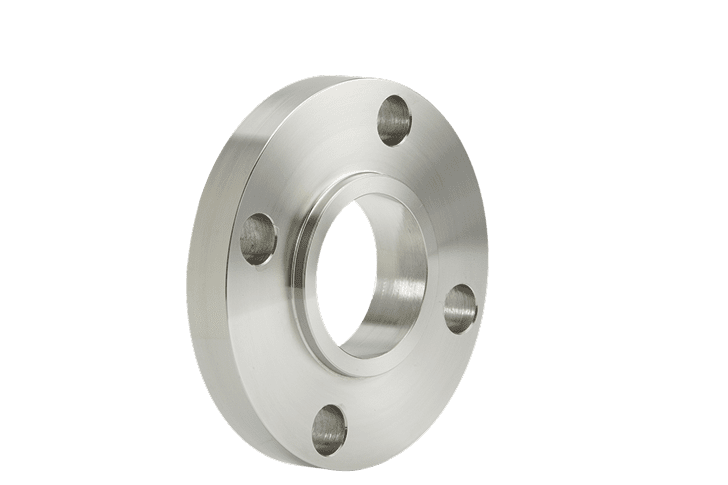

Flange

Slip-On

Flange

Slip-On

Are slipped over the pipe and then welded from both inside and outside to provide sufficient strength and prevent leakage. This flange is used instead of weld necks by many users because of its lower cost and also the fact that it requires less accuracy when cutting pipe to length. Slip-Ons are not normally used in high-stress applications due to low hub and weld attachment.

*Series B Available per customer specifications

Dimensions

- B16.5 / B16.47

- ½” – 36″

- 150# – 2500#

- Series A & Series B

Primary Alloys Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

- ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

Discuss Your Project

Ready to move forward with your project? Take the next step by requesting a quote or talking directly to our experts about industry-specific needs.