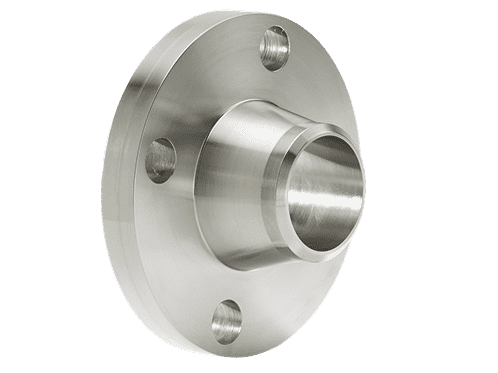

Flange

Weld Neck

Weld Neck Flanges

Also known as a high-hub flange or a tapered hub flange, weld-neck flanges are designed to be joined to a piping system by butt-welding. Weld Neck flanges are preferred when piping is subject to high stresses, high-pressures or subzero/elevated temperatures. The neck, or hub, helps to transmit environmental stress at the flange with the pipe to which it is welded to. The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the flange. Turbulence and erosion are reduced due to the matching bore size of the pipe and flange. These flanges are bored to match the ID of the mating pipe so there is no restriction of flow.

Dimensions

- B16.5 / B16.47

- ½” – 36″

- 150# – 2500#

- Series A & Series B

Primary Alloys Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

- ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

Discuss Your Project

Ready to move forward with your project? Take the next step by requesting a quote or talking directly to our experts about industry-specific needs.