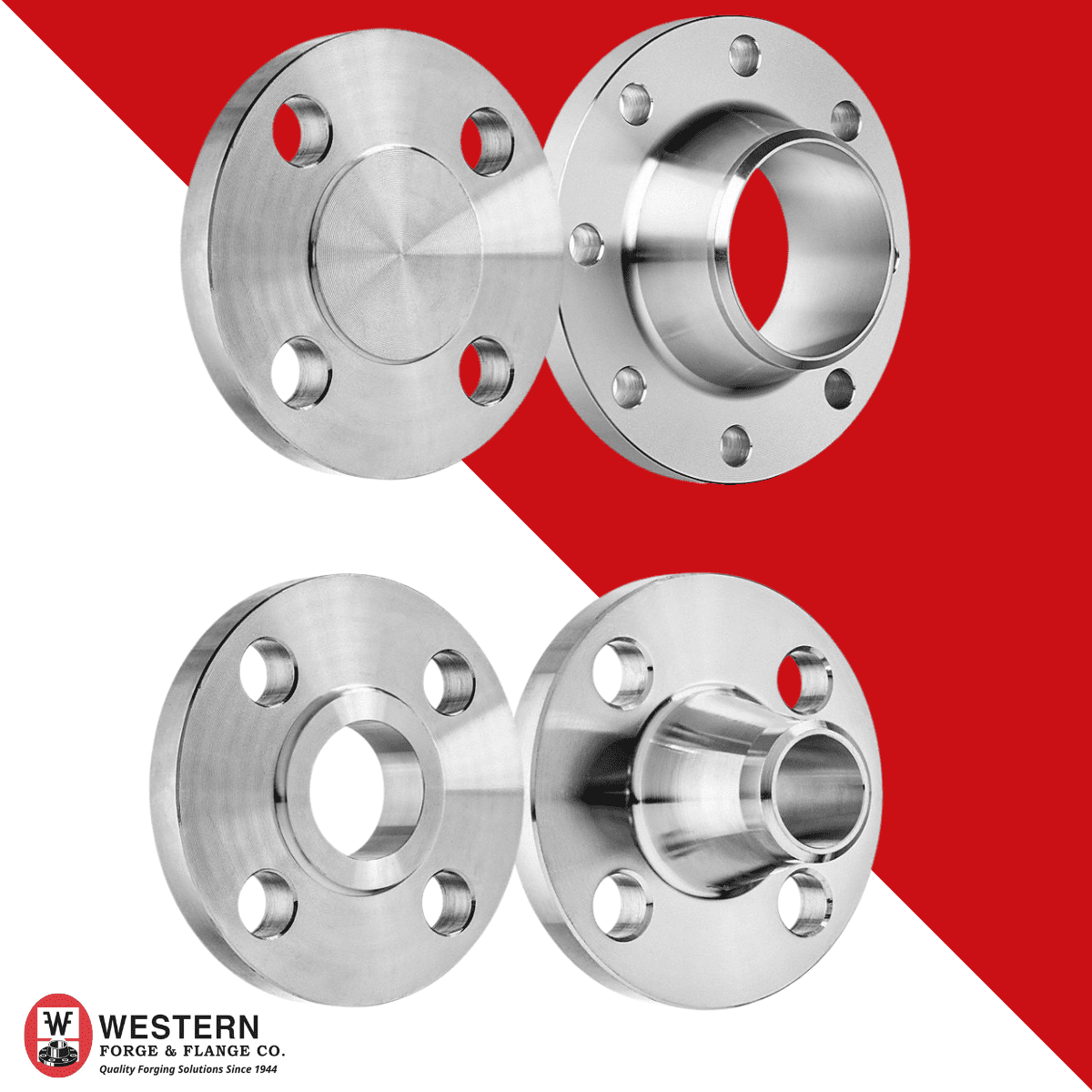

What We Offer

At Western Forge & Flange, we support fabricators, end-users, and distributors with our custom parts, rough forgings (rings, bars, discs, bars), specials, and prototypes. We pride ourselves on offering high-quality materials, fast turnaround times, and adherence to strict quality control standards. Contact us when you need forgings that meet tight tolerances, have unique dimensions, or need to resist pressure, stress, or extreme temperatures.

Emergency Production and Large Contracts

When you’re experiencing costly downtime, you need custom parts in days, not months. Western Forge & Flange’s large inventory of materials allows us to pivot quickly and fulfill your emergency order. Alternatively, we’re just as capable of scaling up to fulfill large, long-term contracts for custom forged components.

Specialized Applications

Over our 80+ years in business, Western Forge & Flange has delivered highly specialized parts for applications including:

- Heavy-duty flanges and forgings for use in abrasive petrochemical plants.

- Aerospace prototype components for commercial rockets.

- Naval and marine hardware adhering to strict U.S. sourcing requirements.

- Nuclear-standard-compliant forgings for reactor environments.

Rings

Up to 75″ in Diameter

Sizes are dependent on alloy selection and thickness

Primary Materials Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

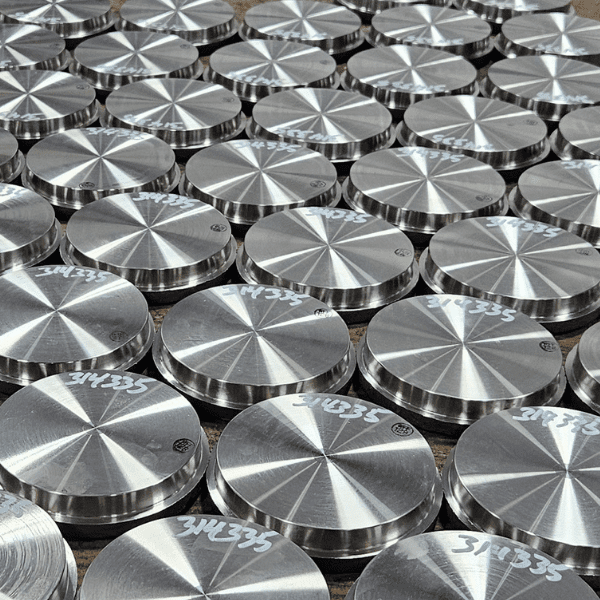

Discs

Up to 50″ in Diameter

Sizes are dependent on alloy selection and thickness

Primary Materials Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

Bars

Up to 48″ in Diameter

Sizes are dependent on alloy selection and thickness

Primary Materials Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

Blocks

Up to 2,500 lbs

Sizes are dependent on alloy selection and thickness

Primary Materials Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Copper Nickel – 70/30, 90/10

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

Materials and Quality Standards

Western Forge & Flange offers over 80 materials, including stainless steels, as well as high-nickel and exotic alloys. We are certified to ISO 9001:2015 and comply with PED, PER, NRC, DFARS, ITAR, CFSI, and other key standards, including nuclear and military specifications. Our meticulous internal quality process includes joint inspection in collaboration with Penn Machine on select projects.

Material Grades

80+ Metals In Stock

Take advantage of our inventory of metals including stainless steel and high nickel alloys.

- Hastelloy – C276, C22, B3, X, G30, G35

- Alloy – 400, 600, 601, 625, 800H/HT, 825, 904L, A20

- Duplex & Super Duplex – 2205, 2507, 255

- Nickel – 200, 201

- Titanium – Grades 2, 7, and 12

- Aluminum – 6061, 3003, 5083, 5086

- Copper Nickel – 70/30, 90/10

- Stainless – 304/H, 310, 316/H, 317, 321/H, 347/H

Why Work With Us?

Western Forge & Flange is your ideal partner for forging. We offer:

- Decades of forging experience since our founding in 1944.

- Fast quotes and on-time delivery enabled by our strong inventory.

- Expertise with special jobs, fast-turnaround prototypes, and large-scale orders.

- Proven service in the highly regulated and demanding nuclear, petrochemical, marine, defense, power, and aerospace industries.

Helpful Resources and Certifications

You can verify that Western Forge & Flange is the right partner for your next demanding custom forging project by reviewing our certifications (including ISO 9001:2015, nuclear, and military standard adherence), available forging dimensions and materials, and content from our Forging 101 section.

Start Your Project

If you’re ready to turn your next custom forging project into a reality, request a quote or speak directly to our team to discuss your order.