Serving Critical Markets

There’s no industrial application too demanding for Western Forge & Flange. Our single-run and multiple-run flanges and custom forgings are used in chemical plants, power generation facilities, shipyards, and other intensive environments.

With over 80 years of experience, numerous certifications, and U.S. materials-sourcing and inspection processes, we can guarantee the quality needed for these jobs.

Markets We Support

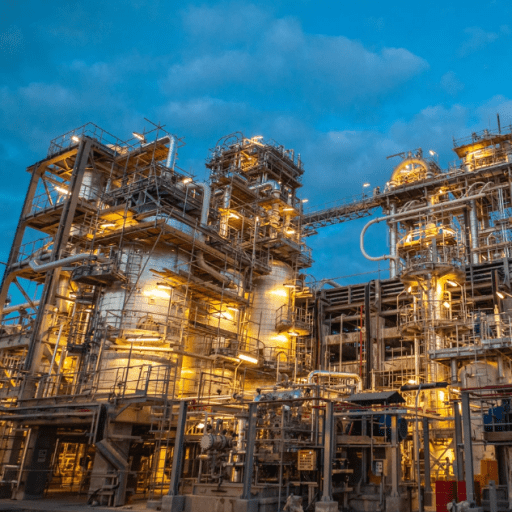

Chemical & Petrochemical

Quick-turnaround, durable, essential parts for acidic, corrosive, and abrasive applications, in over 80 alloys.

Liquefied Natural Gas

Forged components for the production, transport, and storage of liquefied natural gas. Our forgings withstand the most demanding pressures and temperatures of LNG applications.

Oil and Gas

Flanges and special request products for onshore, offshore, subsea, midstream, and downstream projects. We’re committed to helping resolve time-sensitive requests to minimize downtime.

Renewable Fuels

On-demand forgings for hydrogen and other emerging fuels. We offer a full range of components that meet stringent industry standards, ensuring the safety and efficiency of your green energy infrastructure.

Nuclear

Western Forge specializes in flanges for the Nuclear industry, forging metals to exact specifications even on tight deadlines. All components are produced under our ISO 9001:2015 certified Nuclear Quality Program, ensuring full compliance with applicable standards.

Power Generation

Flanges and fittings for the safe and efficient operation of power plants. Our forgings withstand the extreme conditions of power gen applications, including high-temp, high-pressure, and corrosive environments.

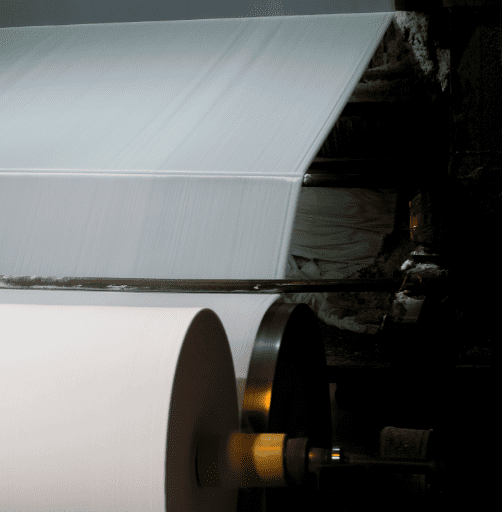

Pulp and Paper

Newer manufacturing methods can result in high corrosion susceptibility. Our use of forged high-performance alloys protects against corrosive substances, extending the life of pulp and paper machinery.

Marine and Shipbuilding

We supply the marine and shipbuilding industry with rugged, reliable flanges and custom forgings built to perform in the harsh, corrosive environments of marine vessels and offshore platforms. Our components are trusted to keep marine operations safe, efficient, and on course.

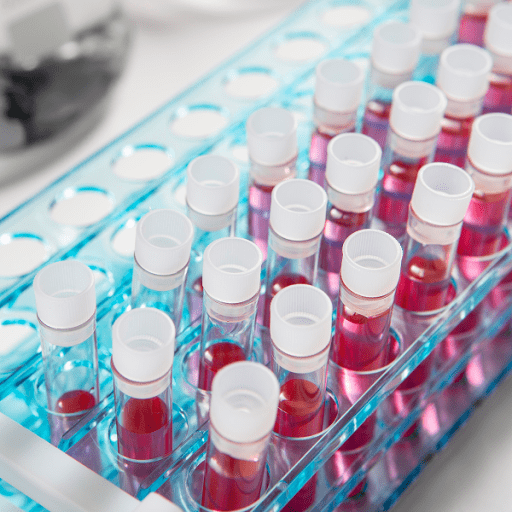

Pharmaceuticals

We produce high-purity, corrosion-resistant forgings made from premium materials essential for sterile processing and fluid management. Our products are manufactured to the strict quality standards required to maintain process integrity, preventing contamination, and ensuring the safety of critical drug production.

Agriculture

Forged parts prolong the life cycle of Agricultural equipment. Reliable nickel-alloy and corrosion-resistant flanges are used for ethanol and biofuel production, filtration systems, agrochemical applications, and agricultural biotechnology.

Mining

We provide the mining industry with flanges and forgings for especially abrasive environments with more than seven decades of metallurgical and forging experience. From zinc and rare earth mines to iron and uranium, Western provides the edge needed to keep equipment running and machines digging.

Defense

We’re a trusted partner to the defense industry, providing forged components that support our troops and safeguard our nation. With over 75 years of experience, we collaborate with leading defense partners to accelerate the manufacturing of next-generation technology.

Why Our Customers Trust Us

Western Forge & Flange is experienced at meeting the most demanding requirements and timelines, with our decades of experience and long list of certifications proving why we’re worthy of our clients’ trust.

We can deliver:

- Emergency high-speed turnarounds, with quotes in minutes and products delivered within five days.

- Compliance with ISO 9001, CRN, nuclear, Naval, and many other standards.

- U.S. materials sourcing and a rigorous inspection process.

- Over 80 years of experience and proven success in demanding, highly regulated industries.

Explore Our Products

Whether you need a specific type of first-rate flange or a custom forging project up to 2,500 lbs, we stand ready to deliver. Our flange offerings span weld neck, slip-on, blind, socket weld, threaded, lap joint, stub end, studding outlet, long weld neck, and orifice set products, ready for use in your industry.

Discuss Your Project

Ready to move forward with your project? Take the next step by requesting a quote or talking directly to our experts about industry-specific needs.